Brief summary

Join us for an exclusive preview of the Bausano Twin-Screw Extruder 125/25 in operation, showcasing the precision and efficiency of Made in Italy quality. On April 28, 2021, at 11 am CT/9 am PT, industry professionals can witness this state-of-the-art compounding line during a live streaming event. Sign up for the webinar to explore Bausano's innovative solutions and hear from Vice President Clemente Bausano about the company's commitment to excellence and future growth.

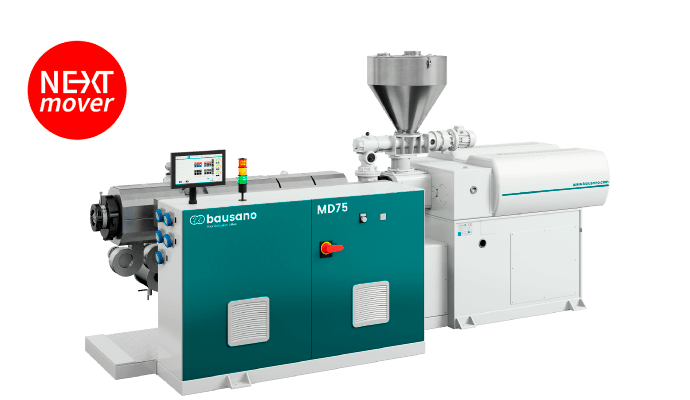

Compounding line with the Bausano Twin-Screw Extruder 125/25, in operation

Made in Italy quality and the precision and efficiency of Bausano are being showcased in an exclusive preview during the live streaming presentation of the MD NextMover 125/25 extrusion line in operation. This exclusive event, open to operators in the plastics processing industry, is scheduled for April 28, 2021, at 11 am CT/9 pm PT. You can sign up for the webinar at the following link:

https://www.bausano.com/digital-lab/usa-virtual-open-day/

Vice President Clemente Bausano will open the event with a speech covering the main benchmarks of the company’s history that led to Bausano to becoming known across the globe as synonymous with reliability and expertise. He will also describe the guidelines and values that support the company’s future growth.

April 28, 11am - US Central Time/9am – US Pacific Time.

This will be followed by a brief introduction to the two MD Plus and MD NextMover ranges, which feature patented Multidrive technology that professionals from the technical team will illustrate in detail. It will conclude with a Q&A session with the participants.

Clemente Bausano, Vice President of Bausano, Italy comments:

“The event represents an important opportunity to provide a preview of the initiatives that Bausano is implementing to effectively respond to the needs of North American customers. In fact, a structured training program for specialized technicians is underway at the Houston and Oswego dealerships, aimed at guaranteeing qualified and prompt assistance, centered around flexibility." He concludes, “Plus, in fall, a twin extrusion line will be installed at our resellers’ showrooms, which operators in the plastics industry can watch in action and have hands-on experience.”

Over the course of the digital event, the Bausano line for the production of flexible PVC granules will reach production levels of 1,000kg/h, with perfectly gelled and high-quality granules.

The Distinct Advantages of Bausano Extruders

In terms of performance, in addition to the patented Multidrive technology, the distinguishing feature of every Bausano extruder is the capacity of the in-house team of engineers to customize every single component based on the specific needs of the customer, including aesthetics. In particular, a fundamental role is carried out by the screws, the heart of the system, with their ad-hoc geometry designed to optimize the processing of the material being extruded.

In addition, the Bausano parallel screws, intermeshing and counter-rotating, are made from nitriding steel, which makes them particularly resistant to abrasion caused by contact with abrasive materials. They are perforated inside so as to allow the circulation of thermostatic oil, with its temperature being adjusted from the control panel. Lastly, guests will have the chance to watch, for the first time, the Smart Energy System in operation, the heating system of the induction cylinder that allows energy savings of about 30–35%.

"According to the recent study published by Market Research Future®, the global market for extruded plastics will reach a value of 281 billion dollars by 2025*," declares Clemente Bausano. He continues, "If we consider the United States, the plastics processing sector is positioned as the eighth largest in the manufacturing world,” and concludes, "Strengthening the presence of Bausano in North America means, therefore, laying the foundations for solid development in a dynamic sector, full of opportunities and needs, which we are ready to seize and fulfil."

* https://www.marketresearchfuture.com/reports/extruded-plastics-market-2100

_607559835b3af.png)