In Brief

The mechanical recycling of PVC waste is a critical aspect of sustainable development, particularly within the construction industry. With its advanced extruders, Bausano plays a vital role in this field, focusing on enhancing the circularity of the PVC value chain. This focus is not only a priority for Bausano but also a significant concern across Europe. The urgency to shift toward PVC circularity reflects the need to promote products made from recycled materials. Bausano acknowledges the importance of developing extrusion lines that contribute to the recovery and circularity of PVC, ensuring that industry practices align with environmental sustainability goals.

What is PVC?

PVC, or polyvinyl chloride, is one of the most widely used plastics globally, known for its versatility and durability. It can be found in a multitude of applications, from pipes and windows to cables and packaging materials. Its properties include resistance to weathering, chemical stability, and affordability, making it a popular choice in various industries. However, the increased usage of PVC has raised concerns regarding its end-of-life management and environmental impact.

Is PVC suitable for recycling?

Yes, PVC is indeed suitable for recycling. The material can be recycled multiple times without significantly degrading its quality. However, the recycling process is complex due to the variety of PVC formulations available, each designed for specific applications. This complexity requires specialized methods to effectively recycle PVC while maintaining its inherent properties.

PVC recycling methods

There are two primary methodologies for PVC recycling: mechanical recycling and chemical recycling.

-

Mechanical Recycling: This method involves separating, grinding, and feeding the ground product into conversion equipment like industrial waste extruders. It is the most common solution in the industry and is preferred when PVC with known composition and traceability is available. Continuous improvements are made to enhance the purity of raw materials and discover new products or uses for recycled material.

-

Chemical Recycling: This approach focuses on converting the plastic back into its constituent raw materials for reuse in the synthesis process or other chemical processes. While effective, chemical recycling is often more expensive and less widely adopted than mechanical recycling.

The process of mechanical PVC recycling

The mechanical recycling process involves several key steps:

-

Reception: Collecting PVC waste from various sources, ensuring it is suitable for recycling.

-

Classification: Sorting the collected waste based on type and quality, ensuring a uniform feedstock for the recycling process.

-

Cutting: Reducing the size of the PVC waste into manageable pieces.

-

Grinding: Further reducing the size of the material to create a fine powder, making it easier to process.

-

Cleaning: Removing any contaminants, such as dirt or labels, to ensure the quality of the recycled material.

-

Casting: Melting the clean, ground PVC into a uniform material that can be shaped.

-

Extrusion: Finally, the melted material is forced through a die to create new products, completing the recycling loop.

This systematic approach allows for effective recycling of mixed PVC waste, enabling the recovery of valuable materials and reducing the amount sent to landfills.

How many times can PVC be recycled?

PVC can be recycled multiple times, with some estimates suggesting that it can undergo the recycling process up to seven times while retaining its material properties. However, the actual number of times depends on the specific applications and the quality of the PVC waste being recycled. Each recycling cycle may require specific adjustments to ensure the recycled PVC maintains the necessary performance characteristics for its intended use.

Bausano flexible PVC extrusion

Bausano has developed a flexible PVC extrusion process that addresses the challenges associated with recycling mixed PVC waste, particularly from post-industrial sources. The goal is to convert mixed rigid/plasticized PVC scrap, which is often difficult to separate due to co-extruded profiles, into new products. The production process can generate significant amounts of scrap, with estimates suggesting around 12% of total production. Historically, this waste has often been sent to landfills, incurring high disposal costs.

-

What are the challenges of recycling PVC?

Recycling PVC presents several challenges, including the need to manage the differing rheological profiles of rigid and flexible PVC, which require varying processing temperatures. Achieving effective blending without degrading the polymer due to excessive heat is a significant technical hurdle. Bausano has tackled these challenges through rigorous testing and process optimization.

The potential applications of recycled PVC compounds are vast. Bausano has identified several viable uses for the recycled material, which may include:

- Pipes: Utilizing recycled PVC to create new piping systems.

- Profiles: Manufacturing new profiles for construction or industrial applications.

- Co-extruded products: Reproducing the original products that generated the waste, thereby closing the recycling loop.

The company aims to achieve a recycled content percentage of over 60% in new products, which meets the threshold for certification as "recycled" under continuous extrusion processes.

What are the examples of PVC recycling?

Bausano has successfully produced several components from recycled PVC, demonstrating the feasibility of the recycling process. Two notable examples include:

-

Co-extruded gasket in flexible PVC extrusion

For the production of the rigid part of a co-extruded gasket, Bausano uses recycled compounds blended with virgin rigid PVC to meet specific hardness targets. The resulting gaskets exhibit excellent dimensional stability and meet all necessary performance requirements, making them suitable for applications such as gates.

-

Single-extruded rod in flexible PVC extrusion

In producing a single-extruded rod, Bausano incorporates recycled compounds with added flexible rigid PVC. The rod produced under optimized conditions performs exceptionally well, surpassing the performance of equivalent products made from virgin material. Its design effectively withstands tensile stresses without leaking, ensuring reliability in practical applications.

Conclusions and future developments

The closed-loop PVC recycling process developed by Bausano not only generates valuable data for research and development but also provides significant advantages for customers adopting this technology. Key benefits include:

- Lower environmental impact: Reducing waste sent to landfills and minimizing reliance on non-renewable resources.

- Economic savings: Companies can lower their disposal costs and streamline their raw material purchasing processes.

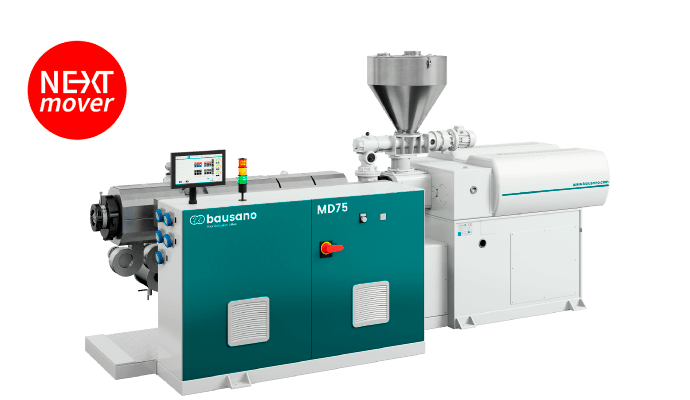

- Energy-efficient systems: Bausano’s induction heating systems can be integrated into the recycling process, further enhancing cost savings and environmental protection.

- Monitoring capabilities: Utilizing the Industry 4.0 Orquestra IoT system, production parameters can be closely monitored for optimal efficiency.

Moving forward, Bausano aims to explore new applications for recycled PVC, potentially incorporating varying amounts of virgin material to expand their product range. By continually refining and optimizing the recycling process, Bausano is committed to leading the way in sustainable PVC recycling, ultimately contributing to a more sustainable future.