Brief summary

PET is one of the most commonly used plastics in consumer products and is found in most water and pop bottles, and some packaging. It is intended for single-use applications; repeated use increases the risk of leaching and bacterial growth. PET plastic is difficult to decontaminate and proper cleaning requires harmful chemicals. Polyethylene terephthalates may leach carcinogens.

Therefore, is it better to recycle PET or not?

What Can PET Plastic Be Recycled Into?

Polyethylene terephthalate (PET) is one of the most widely recycled plastics. Its versatility and durability make it a staple in both consumer products and industrial applications. In the U.S., around 25% of PET bottles are currently recycled, although that rate has room to grow. The PET recycling process involves collecting and processing the used plastic into flakes or pellets that can then be reprocessed into new PET products. Often, these flakes are either molded back into bottles or spun into polyester fibers for use in textiles and other industries. While PET products are recyclable, they are typically not intended for reuse in their original form.

Many in the recycling industry advocate for increasing the recycled PET content in new bottles to promote sustainability and resource efficiency. But there are significant considerations to take into account: how might a rapid shift to higher recycled PET content affect market dynamics and pricing? Two viewpoints on this issue, originally published in a Minnesota Office of Environmental Assistance newsletter, provide contrasting insights into the potential benefits and challenges.

What is PET?

PET or polyethylene terephthalate, is a type of thermoplastic polymer belonging to the polyester family. Known for its lightweight, strong, and transparent qualities, PET is a common choice for bottles, food packaging, and textile applications. It has become the go-to material for beverage containers due to its high strength and resistance to impact. In addition, PET is 100% recyclable, a feature that has driven its popularity in the circular economy. When recycled, PET can be repurposed for various products, conserving natural resources and reducing environmental waste.

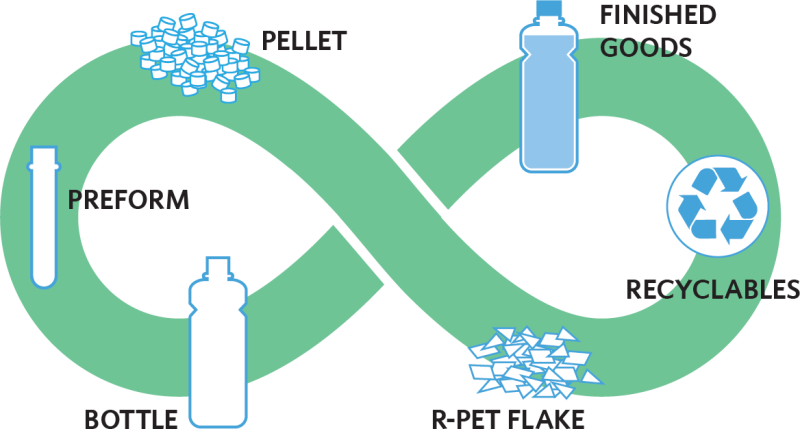

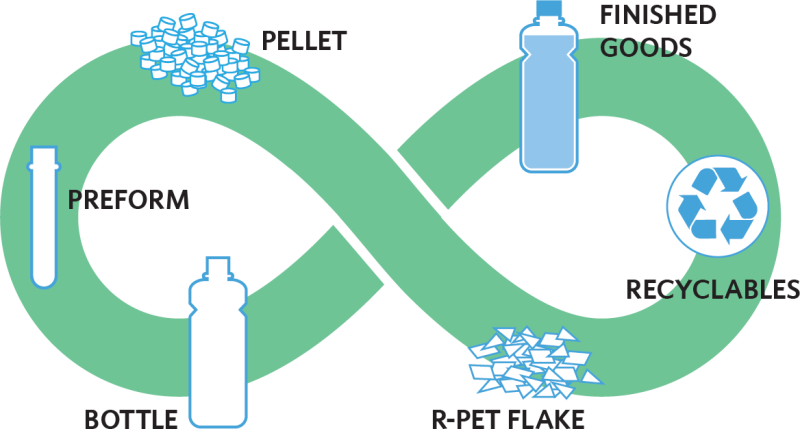

The PET Bottle Recycling Process

Recycling PET bottles involves several detailed steps to transform discarded plastic into usable materials. First, used PET products are collected through various programs, sorted, and thoroughly cleaned to remove contaminants. Once prepared, the PET is crushed and shredded into small flakes. These flakes can either be reprocessed into new PET bottles or spun into polyester fiber. The recycling process is energy-intensive and requires precision to ensure high-quality output, but it results in a versatile material that can meet the needs of different industries.

The PET recycling process plays a crucial role in waste reduction and resource conservation. By reusing PET, manufacturers can reduce their reliance on virgin plastic, which in turn reduces carbon emissions and fossil fuel consumption. This recycling pathway also supports a more sustainable plastic economy by extending the useful life of plastic products.

What are the Uses of Recycled PET?

Once PET has been recycled, it finds new life in a wide range of applications. Recycled PET (rPET) is valued for its strength, flexibility, and resistance to wear, which makes it ideal for everything from textiles to construction materials.

- Polyester Fiber for Clothing and Carpets

One of the most common uses for recycled PET is as polyester fiber in the textile industry. This fiber is used in clothing such as fleece jackets, as well as in carpets and upholstery fabrics. Recycled polyester is an eco-friendly alternative that retains many of the desirable properties of virgin polyester, like durability and moisture resistance.

- Fiberfill for Sleeping Bags and Duvets

The insulating and lightweight qualities of recycled PET make it ideal for fiberfill applications. Used in products like sleeping bags, pillows, and duvets, fiberfill made from PET provides warmth and comfort in a sustainable form.

- Strapping

Recycled PET is also used to create strapping materials. This strong and flexible strapping is commonly employed to secure goods during shipping, as it provides a reliable alternative to more costly materials. Its use in the logistics industry demonstrates PET’s versatility and strength.

- Thermoformed Packaging

PET is also widely used in thermoformed packaging applications, offering clarity, durability, and protection for consumer goods. This recycled plastic can be molded into various packaging forms, meeting the needs of the food, electronics, and cosmetic industries.

- Insulation

The thermal and sound-insulating properties of recycled PET make it a go-to choice for insulation applications in the construction industry. It is often used in walls, roofs, and flooring, where it helps improve energy efficiency.

- Packaging

Beyond its role in bottle production, recycled PET is valuable for other packaging applications. It can be reprocessed into new food containers, medical packaging, and other protective materials, making it a cornerstone of sustainable packaging solutions.

PET Recycling: Should it be Used in Making New Bottles?

As PET continues to play a major role in sustainable packaging, one pressing question remains: should recycled PET be used primarily to create new PET bottles? Opinions vary, with some advocating for increased recycled content in bottles, while others point to market dynamics that complicate this approach. Two perspectives offer insights on the topic:

-

The Case Against More Recycled PET in Containers

Joan Archer, President, Minnesota Soft Drink Association

According to Joan Archer, PET bottles don’t necessarily need to be recycled back into new PET bottles. She argues that the economic value of recycled PET is influenced by numerous market forces, which include:

- Cost of raw materials and virgin resin

- Availability of off-spec resin

- Quality and quantity of collected material

- Expenses associated with collection, transportation, sorting, cleaning, and washing

- Diversity of end uses

Archer contends that recycling PET into bottles is more of a philosophical viewpoint than a data-supported necessity. To date, there is limited evidence showing that recycling PET specifically for new bottle production provides superior environmental benefits or improves the economics of recycling. She suggests that pushing for PET to be recycled back into bottles could potentially disrupt the balance of supply and demand, making recycling less economically viable.

-

The Case For More Recycled PET in Containers

Anne Morse, Solid Waste Officer, Winona County, Minnesota

In contrast, Anne Morse advocates for the use of recycled PET in bottle applications. She argues that recycling has shifted from a simple waste-management activity to a more comprehensive system of resource stewardship. She stresses that all parties—manufacturers, retailers, consumers, recyclers, and haulers—now play a role in creating a sustainable future. Using recycled PET in bottles, she believes, exemplifies this new direction.

Morse asserts that public sentiment is increasingly supportive of responsible resource management, and the concept of stewardship has become central to environmental discussions. Recycling PET into its highest-value applications, including bottles, aligns with future goals for sustainable resource use. According to Morse, this shared responsibility model can lead to efficient recycling systems that work for everyone involved.

The message, as Morse sees it, is that recycling and environmental stewardship are becoming interlinked goals. As the demand for sustainable practices continues to grow, so does the need for a collaborative approach to managing PET and other materials. She concludes that the responsibility to make recycling efficient and effective is no longer solely the job of recyclers; it requires a collective commitment.

In conclusion, the question of whether to use recycled PET in new bottle production is one that involves both environmental and economic considerations. While some argue that recycling PET back into bottles could distort market prices, others believe that it’s a necessary step toward a sustainable recycling future. The recycling industry must weigh the benefits of preserving PET’s highest-value applications against the potential for market disruptions.

As PET continues to be a crucial material in both consumer and industrial applications, finding a balanced approach to its recycling will be essential for long-term sustainability. Whether in bottles or other products, recycled PET offers significant environmental benefits, and encouraging its use in ways that support both economic and environmental goals remains an industry-wide challenge.

_5f105c8b8f32c.jpeg)