Brief summary

Millpolimeros, leading rigid and flexible PVC compound company based in Ecuador, chooses Bausano for the ad-hoc design and manufacture of the extrusion lines for its granules, intended for numerous applications.

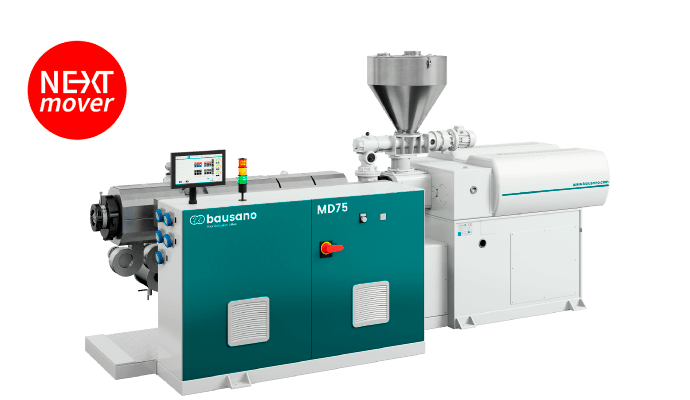

The added value at the basis of the collaboration is qualified pre- and post-sales support, combined with high performance in terms of output (kg/h) and the reliability of the systems, which currently consist of three twin-screw extruders in the MD range.

The added value at the basis of the collaboration

Due to its excellent properties – flexibility, sturdiness, resistance to abrasion, wear and tear, and chemical agents – PVC is an extremely versatile material, used in multiple sectors. According to a study performed by Mordor Intelligence, in the 2021–2026 period the PVC sector in South America will record a CAGR of over 3%.

In this sense, Millpolimeros has found the ideal partner in Bausano when it comes to reaching the goal of producing perfect granules that comply with the technical specifications of customers, significantly reducing lead time.

The technical consultancy from Bausano engineers has made a difference in the customization of the machines’ components, from the screws to the end-of-line accessories, creating conditions for much higher productivity levels than those expected: thanks to a yield of 120% on the processing of some materials, the expectations of Millpolimeros have, in fact, been more than exceeded. In addition, the customer was very happy with the machines’ ease of use, which means that they can immediately be put to work.

Higher productivity

“From the very first extrusion line, we have built an excellent trust-based relationship with Bausano,” stated María Victoria Navas, CEO of Millpolimeros, who continued: “Being able to share this challenge, born under the sign of innovation, has been a source of great pleasure for us. Using solutions conceived specifically based on the mix to be granulated has allowed us to promptly meet our customers’ needs.” She concludes: “A success also made possible by Bausano’s first-rate customer service.”

_60377f8745323.jpeg)