-

COMPLETE LINES

-

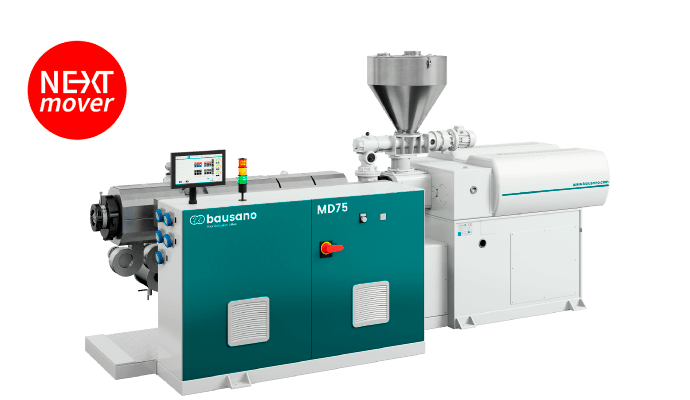

EXTRUDERS

Laboratory Extruder MD 30

MD 30 extruder allows to carry out tests, samples and experiments on small quantities

-

DOWNSTREAM

-

INDUSTRIES

-

KNOW HOW

-

SERVICE

Technical support

Technical assistance for our Extrusion Line with well-trained technicians with hands-on support as well remote assistance.

Spare PartsBausano well-stocked warehouse where you can find accessories and original spare parts, even for Bausano machines over 20 years old

Testing & TrainingTesting services like Factory acceptance tests, virtual FAT or SAT are offered with all our Extrusion Lines

- REQUEST A QUOTE