Brief Description

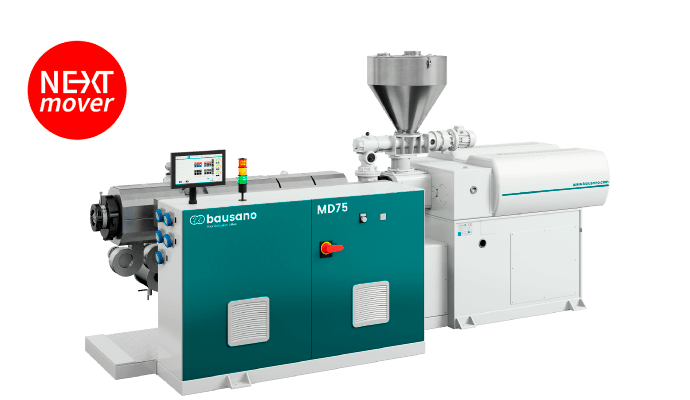

Bausano announces the updating of the twin-screw and single-screw lines dedicated to the extrusion of soft and rigid, transparent, filled or press-filled PVC pipes and pipes in PO, such as PP, PE HDPE and LDPE.

PVC pipe extrusion technology, based on Bausano’s MD and E-GO ranges, enables production of different types of pipes: rigid or flexible, mono or multilayer, smooth or corrugated, for varied applications: from construction to agriculture and also medical. Every detail is customised according to the customer’s production goals, in order to guarantee excellent melt homogeneity, process flexibility, maximised output and reduced energy consumption.

High-performance double-exit die head for PVC pipe extrusion processes

Bausano innovations include the high-performance extrusion line for PVC pipes – for diameters ranging between 63mm and 160mm – consisting of the MD Nextmover 170/30 model equipped with a double-exit die head, for overall production of 2,000kg/h. The gravimetric doser is designed to ensure maximum precision with the amount of infeed material so that the pipes in outfeed weigh the same. In addition, the top-of-the-range version has bimetallic screws and cylinder that are subjected to less corrosion and wear, thereby resulting in a longer component life.

Other factors that are essential for the success of the entire PVC pipe extrusion process are the cooling and calibration benches, made from stainless steel, for pipes that are cut perfectly to size and have a flawless surface. Specifically, the line with a double-exit die head has two 9-m parallel calibration benches in the two-chamber configuration, with temperature and water level control, which allows different vacuum conditions to be created as required. In addition, the high-performance pipe cooling system cools the pipes faster, thereby improving their quality and taking up less space when installing the line. Bausano’s offer is completed with end-of-line accessories, including the drive system, cutting unit and the belling machine.

Innovative PVC pipe extrusion systems by Bausano

Two innovative systems also ensure plant energy efficiency: on the one hand, the Smart Energy System, with its electromagnetic induction principles, enables more rapid and uniform heating of the cylinder and, therefore, of the material being processed, for savings of up to 35%; on the other hand, through Digital Extruder Control 4.0, which has a 21-inch screen, it is possible to accurately monitor consumption of every single stage of the process. The real-time performance display enables intervention to manage motor power, temperature, oil control unit inspection, screw adjustment and other parameters, on request.

Experience at the service of PO and PVC pipe extrusion lines

Lastly, the line meets the Smart Factory vertical integration requirements and is able to communicate with third-party systems, such as Bausano’s sophisticated in-line measurement tool for accurate control of the internal and external diameter and wall thickness of the pipe.

Expansion of the PO and PVC pipe extrusion lines is the result of our unique ability to combine process consultancy, passion for innovation and technological expertise. In this regard, Bausano has recently reinforced its Technical Department by adding a team of experts with specific skills and consolidated know-how of designing these types of solutions. The goal is to meet the needs of manufacturers as an important partner by combining turnkey, highly customisable systems with top-rate services, thanks to dedicated on-site technicians.

Pipe Extrusion Lines for reduced energy consumption

As pioneers in the extrusion industry, we at Bausano are committed to advancing PVC & PO pipe production technologies that not only increase operational efficiency but also prioritize environmental sustainability. Our latest enhancements to extrusion lines are designed to meet the modern demands of efficiency and energy conservation. With these innovations, we equip our clients with superior tools to excel in a competitive market while supporting global environmental goals. We invite industry leaders and partners to join us in this journey towards a more sustainable future.